An Overview Of Woodwork Hand Tools.

A quality set of hand tools, including chisels, hand saws, sharpening tools, mallets, hammers, and carving tools, should always be kept in any woodworking shed.

In fact, there are many woodworkers around that actually prefer to use hand tools rather than power tools.

This could be motivated by a desire to learn about ancient Chinese or Japanese woodworking traditions, or simply a desire to see how much you can do with only two hands.

Whether you’re a professional woodworker or a beginner hobbyist, you might be interested in the knowledge and potential satisfaction of working solely with hand tools.

Below Is A Woodworking Hand Tools Overview.

1. What is an Adze: An adze is a traditional cutting tool that resembles an axe, but its cutting edge is perpendicular to the handle rather than parallel to it.

a. They have existed since the Stone Age.

b. In hand woodworking, adzes are used to smooth or cut wood.

2. What are Auger Bits: The Auger is a tool that is used to drill holes in wood.

a. It has six parts: a screw, spurs, cutting edges, twist, shank, and tang, and it looks like a corkscrew.

b. The screw, which resembles a tapered wood screw and has a small diameter, centres the bit and draws it into the work.

3. What are Awls and what are they used for: A scratch awl is a layout and point-making tool used in woodworking.

a. When constructing woodworking joints and other processes, it is used to scribe a line that will be followed by a hand saw or chisel.

b. The scratch awl is essentially a steel spike with a finely sharpened tip.

4. What do we use a Punch Tool for: A punch is a tool that is used to make an indent or a hole in a hard surface.

a. A hard metal rod with a narrow point on one end and a broad flat butt on the other is typically used.

b. To strike a punch, most woodworkers use a ball-peen hammer.

5. What is a Gimlet: A gimlet is a hand tool that is used to drill small holes in wood without causing it to split.

a. It’s essentially a semi-cylindrical piece of steel with a cross handle on one end and a worm or screw on the other, hollow on one side.

6. What is a Carpenters Axe or Hatchet: Carpenter’s axe & hatchets are smallish axes that are used in traditional carpentry and joinery.

a. Carpentry axes have a long straight edge that gives high cutting stability as well as being the optimum shape for guiding the blade by eye.

7. What is a Swing Brace: A woodworking swing brace is used to bore holes ranging in size from 1/4” to 1 1/2” in diameter, which are typically too large for a hand drill.

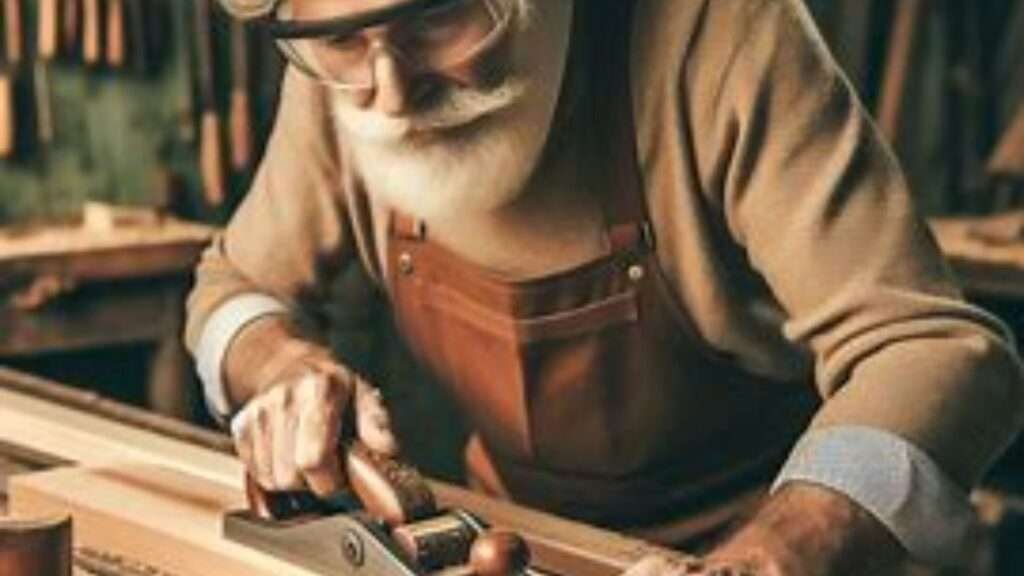

8. What is a Hand Plane: A Hand Plane is essentially used for removing rough surfaces on wood and for reducing it to size.

a. There are a few different types of Woodwork Planes (Scrub, Bench, Japanese & Specialist) and are made in a variety of sizes.

9. What is a Gauge or Marker: A gauge or marker is used to marking lines for cutting or other tasks.

a. The gauge’s job is to scribe a straight line parallel to a reference edge or surface.

b. It’s widely utilised in joinery.

10. What are Files used for: Files shape, trim, and smooth wood.

a. There is about 8 different types of files used for woodworking.

b. Rasps are files made specifically for wood.

11. What are Woodworking Mallets: In woodworking, wooden mallets are used to force wooden parts together, such as when assembling dovetail joints or pounding dowels or chisels.

a. Metal hammers can damage wood surfaces or chisel ends, whereas a wooden mallet will not harm either wood surfaces or tools.

b. Because it strikes with less force than a metal hammer, a wooden mallet makes it easier to manage a chisel.

c. A rubber mallet striking the chisel would be ineffective due to the excessive bounce.

12. What is a good brand of Claw Hammer: A claw hammer is a type of hammer that is primarily used for driving nails into or withdrawing nails from wood.

a. The handle is typically composed of wood, fibreglass, or steel, and the head is made of steel.

b. One side of the head is flat, with a smooth or rough surface and is used to pound another surface.

c. When pulling out a nail, the rounded end of the claw, in conjunction with the handle, is utilised to gain leverage and get the job done.

d. Estwing hammers are one of my personal favourites and are ‘built to last’ in the USA.

e. Estwing is a household name in the world of hammers, producing hammers that are both visually appealing and robust one-piece steel nail drivers with outstanding shock absorption.

f. This particular hammer weighs 16 ounces (Claw hammers typically weigh 16 to 25 ounces).

g. It has a smooth face and a 13 Inch steel handle & a Shock Reduction Grip.

13. What is a Coping Saw: A coping saw is composed of an extremely thin metal blade stretched across a metal u-shaped frame and is ideal for making turning cuts on wood, plastic, or metal, depending on the blade used.

a. Each end of the U-shaped frame has a swiveling spigot to hold the blade ends.

b. They usually have a wood or plastic handle, and the operator can turn the blade while cutting.

c. You can get Coping Saws that have 360-degree teeth that will cut in any orientation or direction, making them ideal for cutting any form of curve, contour, notch, v, or spiral.

d. The ones I’ve seen also have a very comfortable handle and ideal for any woodworker or DIY’er.

14. What is a Japanese Saw/Pull Saw: Japanese saws cut materials by pulling and are hence referred to as “pull saws” (European Saws are typically referred to as “Push Saws”).

a. Pull saws are lower in weight, need less power, and produce a cleaner edge.

b. This saw is manufactured of high-quality Japanese steel and includes universal teeth for cross, rip, and slant cutting.

15. What is a Dovetail Saw: A dovetail saw is a small backsaw used to cut dovetails.

a. A Dovetail Saw/backsaw is any hand saw that has a stiffening rib on the edge opposite the cutting edge.

b. A Dovetail saw typically has more teeth per inch (around 15-20 TPI), with teeth sharpened in a rip tooth pattern and minimal set to leave a narrow kerf.

c. This fine rip tooth pattern is also useful for cross cutting.

16. What is a Chisel Hammer: A chisel hammer is a hammer designed specifically for striking the end of a chisel handle to chop and cut wood and assembling joinery when building furniture.

a. The head of a chisel hammer is typically constructed of nylon, steel, or brass.

b. A Dai Dogyu chisel hammer is forged from high-quality tool steel and carefully tempered to be robust, hard, and long-lasting.

c. Each Dai Doguy chisel hammer is expertly crafted for balance and control and Japanese White Oak is used for the handles.

Stay Safe When Using Woodwork Hand Tools.

To avoid accidents and stay safe on the job, it’s critical to understand how to use any woodworking tool correctly, especially hand tools.

As a result, if you’re not sure, take the time to do some research on using specific tools.

Get the most out of your tools when working on a project, but also arm yourself with knowledge that will help you avoid injury or damage to your tools.

Clean and oil you hand tools to keep them clean and properly preserved in your shed.

Quality tools that have been properly maintained can be passed down from generation to generation as they can withstand the test of time.

Unfortunately, there are still far too many injuries associated with the use of hand tools; therefore, it is necessary to observe a few basic safety rules when using hand tools as follows:

1. Regularly maintain all tools to keep them in good working order.

2. Make use of the appropriate tool for the job.

3. Before using a tool, inspect it for damage and do not use it if it is damaged.

4. Follow the manufacturer’s directions when using tools.

5. Personal protection equipment (PPE) should be provided and always used properly.

It Is Potentially Dangerous To Use The Wrong Hand Tool.

When a chisel is used as a screwdriver or a screwdriver is used as a chisel, the tool’s tip may break and fly off, potentially injuring the user or another person.

Use woodworking hand tools only for their intended purpose and always keep your tools in good working order.

If a hand tool’s wooden handle is loose, splintered, or broken, the tool’s head may fly off and injure the user or another person.

Damaged or worn-out tools need to be fixed or replaced and for goodness sake, don’t continue using them.

Although not a woodworking tool, a good example that comes to mind from working on the care is a cheap spanner with spread jaws.

A spanner with spread jaws could easily fall off the job and you could end up with a hand injury.

Impact tools with mushroomed heads, such as chisels, wedges, and drift pins (metal working), are particularly hazardous as when struck, the heads may fracture, releasing sharp fragments into the air at high velocity.

Hand Tools With Blades.

Bladed tools are especially dangerous since they can inflict injuries such as cutting, slicing, snipping, and stabbing; its common sense that you should be wearing cut resistant gloves when using bladed tools.

To avoid harm when using bladed tools, keep blades sharp and inspect them on a regular basis, the reason for this is that dull blades are difficult to wield and control and they can be substantially more dangerous than well-maintained blades.

Safety knives are often provided in most workshops to reduce the risks associated with using bladed devices.

Walkways / aisles should be kept clear of bladed tools.

If a sheath or protective covering is provided be sure to use them when storing your bladed tools.

Impact tool safety.

Inspect an impact tool for mushroomed heads, cracks, chips, or other evidence of wear and tear before using it.

Always wear safety glasses or safety rated vision glasses when using impact tools.

Although not a huge risk these days as ‘non-sparking’ tools are more often used than not, when working with impact tools, fire is a possible risk that was often overlooked in the past.

These tools can create sparks, which can ignite fumes, oxygen, paper, or solvents in your work space, so if you’re not able to use non-sparking impact tools, treat these situations similar to when doing hot work and keep away from flammable materials and fumes.

Managing Hand Tools Risks.

Woodworking hand tools can cause cuts, burns, scratches, sprains, eye injuries, hearing loss, fractured bones, and even lung disorders.

The use of certain woodworking hand tools can cause a lot of dust and other particles to be released into the air.

Sandpaper, planes, files, and saws, for example, will create sawdust and depending on what type of wood you’ve been processing, the sawdust can contain oils and sometimes nasty compounds.

Short-term exposure can cause minor irritation, but long-term exposure can result in chronic bronchitis, pneumonia, and other respiratory issues.

Use filtering masks and eye protection when working with a dust-generating tool.

Traditional Woodworking Safety.

A traditional woodworker uses traditional joinery, techniques, tools, and processes to make beautiful, high-quality wood objects that will just about last forever.

I prefer to work with woodworking hand tools, but thanks to the fantastic high quality power equipment accessible these days, superb traditional style wood products can also be made via power tools.

I enjoy using traditional woodworking hand tools, but they may be difficult to learn if you don’t have the right tools and can be dangerous if you don’t know how to use them correctly.

If you have the money, invest in high-quality tools, and if you have the time, devote plenty of hours towards learning how to use them effectively.

It is vital to understand how to use hand tools correctly, it’s a matter of ‘practice makes perfect’ folks.

Practice with them until you are confident and very comfortable with how each tool feels in your hand.

Always maintain a sturdy and balanced stance with correct body posture while working with hand tools; this will help you avoid injuries.

Constant pressure on the handle of a hand tool can cause sensitivity loss in your fingers or hand, making proper operation difficult and this is an important safety concern when using hand tools for long periods of time.

As a result, selecting tools with excellent ergonomic design is a very good idea.

Always use the right type of personal protective equipment (PPE) and make sure it is in good condition.

There will be occasions when I will use a combination of woodworking hand and power tools, so having a good selection of PPE to suit all of these different conditions is essential.

Learn the principles of hand tools to better comprehend traditional woodworking, and you’ll realize that some wood projects are actually faster with hand tools.

A Few Words on Hand Saw Safety.

In woodworking and construction, the hand saw is one of the most essential hand tools for cutting pieces of wood into various shapes.

To operate a handsaw correctly, make sure it’s sharpened and the blade is straight before you begin cutting, measure and draw a pencil line on the area you’ll be cutting and then, make a gentle, precisely straight cut down the line, keep your elbows in by your sides and properly angle the saw.