Woodworking Hand Tools Comprehensive Guide.

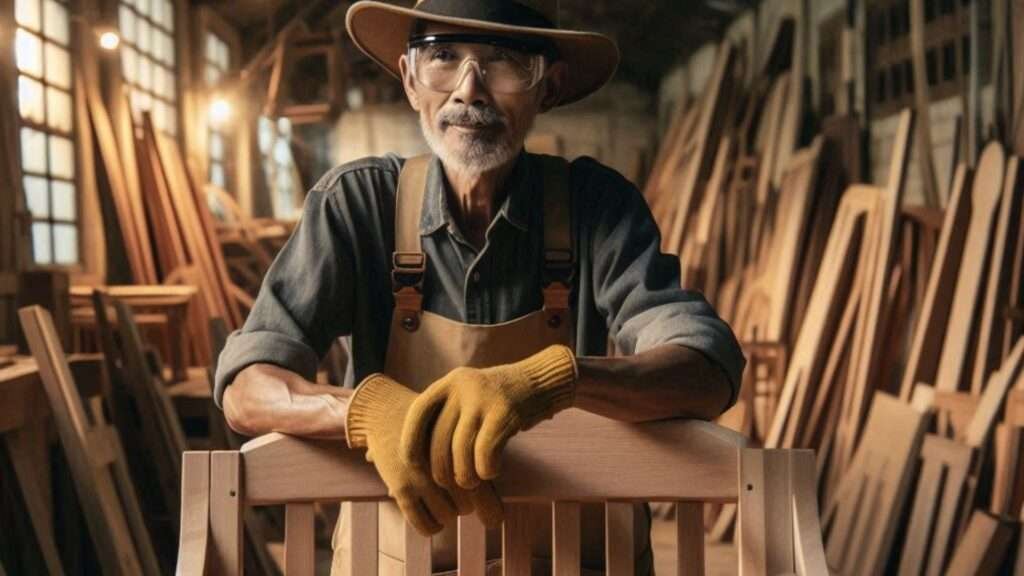

Woodworking is an intricate craft that requires precision and skill, and having the right hand tools in your shed is crucial to achieving quality results.

The cornerstone of any woodworker’s toolbox includes a selection of essential tools that are indispensable for a variety of tasks.

Among these, chisels, hand saws, hand planes, and marking gauges stand out as fundamental instruments.

Chisels are vital for fine detail work and carving. They come in various sizes and shapes, designed to accomplish tasks ranging from rough shaping to intricate detailing.

A set of high-quality chisels allows for precise cutting and shaping of wood, making them a must-have in any woodworker’s arsenal.

Hand saws are essential for cutting wood to size. There are several types of hand saws, including the rip saw, crosscut saw, and dovetail saw, each serving a specific purpose.

Rip saws are designed for cutting along the grain, while crosscut saws are used for cutting across the grain. Dovetail saws are ideal for precise joinery work. Investing in a variety of saws ensures versatility in your woodworking projects.

Hand planes are indispensable for smoothing and leveling wood surfaces. They come in different types, such as the jack plane, smoothing plane, and block plane, each suited to specific tasks. A well-tuned hand plane can produce a smooth, even surface that is difficult to achieve with power tools alone.

Marking gauges are crucial for accurate measurements and layouts. They help in marking lines parallel to the edge of a workpiece, ensuring precision in cutting and assembly.

A reliable marking gauge can significantly improve the accuracy of your work, making it an essential tool for any woodworker.

In addition to these fundamental tools, other essentials include a set of screwdrivers, a mallet, a combination square, and a sharpening stone.

Each of these tools plays a critical role in various woodworking tasks, from assembly to finishing.

Investing in high-quality hand tools not only enhances the quality of your work but also ensures longevity and reliability in your woodworking endeavors.

Proper Maintenance and Sharpening of Different Types of Hand Saws.

Ensuring the longevity and performance of your hand saws, including crosscut saws, rip saws, and dovetail saws, necessitates proper maintenance and sharpening.

Regular upkeep not only enhances cutting efficiency but also prolongs the lifespan of these essential woodworking tools.

Firstly, it is crucial to clean your saws after every use. Removing sawdust and resin build-up with a brush or compressed air prevents deterioration and maintains blade sharpness.

Additionally, applying a light coat of oil can prevent rusting, especially if the saws are stored in humid environments.

Sharpening hand saws requires specific tools: a saw vice to hold the saw securely, a saw file appropriate for the type of saw, and a saw set to adjust the teeth.

For crosscut and rip saws, a triangular file is typically used. Begin by securing the saw in the vice, ensuring that the blade is stable.

To sharpen a crosscut saw, file each tooth at a 60-degree angle to create a knife-like edge. Alternate filing each tooth from opposite sides of the blade to maintain an even set.

For rip saws, file each tooth straight across at a 90-degree angle, mimicking a chisel edge. This technique allows the saw to cut along the grain more effectively.

Dovetail saws, known for their fine and precise cuts, require meticulous attention. Use a fine-toothed saw file and gently file each tooth, maintaining the original angle.

It is essential to check the set of the teeth regularly. A saw set tool can adjust them, ensuring they are evenly spaced and not too wide, which could cause binding or rough cuts.

Honing the blade with a strop or fine-grit stone can remove any burrs and refine the edge.

Consistent maintenance and sharpening of hand saws will result in cleaner, more accurate cuts and a more enjoyable woodworking experience.

By following these best practices, you ensure your saws remain in optimal condition, ready for any woodworking project.

The Differences Between Western and Japanese Hand Planes.

Hand planes are essential tools in woodworking, and their design and functionality can significantly impact the quality of the work produced. Among the most popular types are Western and Japanese hand planes, each with unique characteristics rooted in their cultural and historical contexts.

Western hand planes, traditionally designed in Europe and North America, are characterized by their robust, often cast-iron bodies and adjustable mechanisms.

These planes generally feature a bevel-down blade, which is held in place by a lever cap and adjusted using a screw or knob.

This design allows for precise control over the blade’s depth and angle, making Western planes highly versatile for a range of woodworking tasks.

The materials used in Western hand planes typically include high-carbon steel for the blade and durable metals for the body, providing longevity and reliability.

In contrast, Japanese hand planes, known as “kanna,” have a simpler, more minimalist design.

These planes feature a wooden body, often made from oak or other hardwoods, and a blade that is set bevel-up.

Unlike their Western counterparts, Japanese planes are pulled towards the user rather than pushed away.

This design philosophy aligns with traditional Japanese woodworking practices, which emphasize pulling motions for greater control and accuracy.

The blades in Japanese hand planes are usually made from laminated steel, combining a hard cutting edge with a softer, more resilient backing.

There are distinct advantages and disadvantages to each type of hand plane. Western planes are celebrated for their adjustability and ease of use, making them suitable for a wide range of woodworking tasks, from rough shaping to fine finishing.

However, their weight and complexity can be a drawback for some users. On the other hand, Japanese hand planes offer exceptional sharpness and a tactile connection to the wood, which many craftsmen find beneficial for fine detail work.

Their simplicity, however, means they require more skill to set up and maintain correctly.

When choosing between Western and Japanese hand planes, consider the specific needs of your woodworking projects.

If you require a versatile tool with adjustable features, a Western hand plane may be ideal.

However, if you are looking for precision and a deeper connection with your craft, a Japanese hand plane could be the better choice.

Choosing Chisels for Different Woodworking Tasks.

When embarking on woodworking projects, selecting the appropriate chisels is crucial for achieving precise and efficient results.

Understanding the different types of chisels and their respective applications can significantly impact the quality of your work.

Among the primary chisels are bench chisels, mortise chisels, and paring chisels, each designed for specific tasks.

Bench chisels are versatile and commonly used for general-purpose woodworking. They are ideal for tasks such as cutting and shaping wood, making joints, and trimming.

Mortise chisels, however, are specifically designed for heavier tasks like chopping out mortises. Their thicker blades and robust construction make them suitable for withstanding significant force.

Paring chisels, on the other hand, are used for delicate, detailed work, such as cleaning up joints and shaving off thin slices of wood. Their long, thin blades provide precision and control, making them indispensable for fine woodworking.

The material of the chisel blade is another critical factor to consider. High-carbon steel chisels are prized for their sharpness and durability, although they may require more frequent sharpening.

Alternatively, chrome vanadium steel chisels offer good edge retention and are relatively easier to maintain.

Blade shape also plays a role; beveled-edge chisels are versatile for reaching tight corners, while straight-edge chisels provide strength for heavy-duty tasks.

Handle types can affect both the comfort and control of the chisel. Wooden handles are traditional and provide a good grip, while plastic or composite handles offer durability and resistance to wear.

The balance of the chisel, which is influenced by the handle and blade length, ensures that the tool feels comfortable and controlled in hand, reducing fatigue during extended use.

Selecting the right chisel involves considering the type of woodworking task, material, blade shape, and handle design.

By matching the chisel to the specific requirements of your project, you can enhance both the efficiency and precision of your woodworking endeavors.

Hand Tool Techniques vs. Power Tool Techniques.

In woodworking, both hand tools and power tools serve critical roles, each offering unique advantages and limitations.

Hand tool techniques often prioritize precision, control, and the tactile experience, allowing woodworkers to create intricate details and fine adjustments.

For instance, using a hand plane to smooth surfaces or a chisel for joinery offers a level of finesse that power tools might not achieve.

The manual effort required in hand tools also provides a deeper connection to the material, enhancing the overall craftsmanship.

Conversely, power tools excel in efficiency and speed, making them indispensable for tasks requiring substantial material removal or repetitive actions.

Tools like table saws, routers, and power sanders can accomplish in minutes what might take hours with hand tools.

This efficiency is particularly advantageous in large-scale projects or when working with harder woods.

However, power tools can sometimes lack the nuanced control that hand tools offer, which might be critical for detailed work or delicate operations.

One notable advantage of hand tools is their ability to perform tasks with minimal noise and dust, creating a more pleasant and environmentally friendly workspace.

Moreover, hand tools do not require electricity, making them more versatile in remote locations or during power outages.

On the other hand, power tools are generally more ergonomic, reducing physical strain on the user and allowing for longer working sessions.

Examples of tasks where hand tools might be preferable include fine joinery, detailed carving or working with fragile materials where precision is paramount.

In contrast, power tools are ideal for ripping large boards, cutting complex shapes, or performing extensive sanding.

Ultimately, the choice between hand tool techniques and power tool techniques depends on the specific requirements of the project and the personal preferences of the woodworker.

Mistakes Beginners Make with Hand Tools and How to Avoid Them.

Woodworking with hand tools presents a unique set of challenges, especially for beginners. One prevalent mistake is improper tool handling.

Many novices grip tools too tightly, which not only reduces control but also causes unnecessary fatigue.

It’s essential to maintain a relaxed yet firm grip, allowing for smoother and more precise movements. Practicing with scrap wood can help acclimate to the correct handling techniques.

Another frequent error involves incorrect sharpening techniques. Sharp tools are critical for clean, accurate cuts.

Beginners often overlook the importance of maintaining a consistent angle while sharpening, leading to uneven edges and poor performance.

Investing in a quality sharpening guide can make this task easier, ensuring that blades remain sharp and effective.

Regularly honing tools rather than waiting for them to become markedly dull is another good habit to develop.

Poor project planning is also a common pitfall. Rushing into a project without careful planning can result in wasted materials and time.

Beginners should take the time to sketch out their designs, measure carefully, and create a step-by-step plan.

This forethought helps in anticipating potential issues and ensuring that all necessary tools and materials are on hand before beginning.

Additionally, many beginners make the mistake of neglecting to understand the specific purposes of different hand tools.

Using the wrong tool for a job can lead to unsatisfactory results and even damage to the tools or workpiece.

Learning the distinct functions of each tool and practicing their correct application is crucial.

Building good habits early on is vital for improving woodworking skills. Beginners should adopt a mindset of continuous learning, viewing mistakes as opportunities for growth.

Joining woodworking communities, taking classes, and seeking feedback from more experienced woodworkers can provide valuable insights and enhance one’s abilities over time.

By recognizing and addressing these common mistakes, beginners can develop a strong foundation for their woodworking journey.

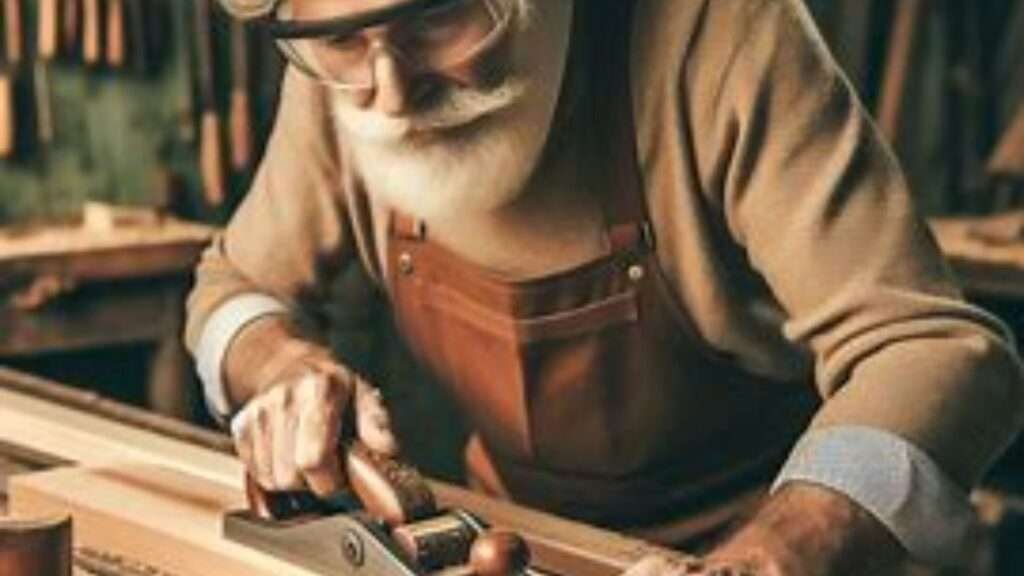

The Proper Technique for Using a Hand Plane.

Achieving a glass-smooth surface with a hand plane is a fundamental skill in woodworking, requiring meticulous attention to detail.

The first step is to ensure your tool is properly set up. Begin by selecting the right hand plane for your task; a bench plane is typically ideal for smoothing surfaces.

Next, focus on blade sharpness. A razor-sharp blade is crucial for clean, precise cuts. Sharpen your blade using a whetstone or a honing guide to maintain a consistent bevel angle.

Blade adjustment is the next critical step. The blade should protrude slightly from the mouth of the plane, approximately the thickness of a sheet of paper.

This fine adjustment helps in avoiding tear-out and ensuring smoother cuts. The lateral adjustment lever allows you to align the blade parallel to the sole of the plane, ensuring even shaving across the wood’s surface.

When planing, start with the wood grain. Always plane in the direction of the grain to minimize tear-out and achieve a smoother finish.

Hold the plane firmly with both hands; place one hand on the front knob and the other on the tote. Apply even pressure throughout the stroke, maintaining consistent contact with the wood.

Begin with a light cut to gauge the wood’s response, and gradually increase the depth if necessary.

Recognizing and addressing common issues, such as tear-out and uneven surfaces, is essential for optimal results.

Tear-out occurs when the grain is lifted rather than sliced, often due to a dull blade or planing against the grain.

To remedy this, ensure your blade is sharp and adjust your planing direction. For uneven surfaces, check for high spots using a straightedge and focus your planing efforts on these areas until the surface is uniformly flat.

By following these steps and techniques, you can effectively use a hand plane to achieve a glass-smooth surface, enhancing the quality and appearance of your woodworking projects.

Remember, practice and patience are key to mastering this essential woodworking skill.

Vintage Versus Modern Hand Tools: Quality and Performance.

The debate between vintage and modern hand tools is a familiar one among woodworkers, each bringing unique qualities and performance characteristics.

Vintage hand tools are often lauded for their superior craftsmanship and the high-quality materials used during their production.

These tools were typically made with durability in mind, featuring robust metals and fine wood handles that have stood the test of time.

For instance, a well-maintained vintage Stanley plane can still perform admirably in a modern workshop, thanks to the meticulous manufacturing processes of its era.

On the other hand, modern hand tools benefit from advancements in technology and design.

Innovations in metallurgy have resulted in stronger, more durable blades, while ergonomic designs have enhanced user comfort and efficiency.

Modern manufacturers, such as Lie-Nielsen and Veritas, incorporate these advancements to produce tools that offer precision and reliability.

Furthermore, contemporary tools often come with warranties and customer support, which can be reassuring for woodworkers investing in new equipment.

However, both vintage and modern hand tools come with their respective pros and cons. Vintage tools, while often more aesthetically pleasing and characterful, may require restoration and maintenance.

This can be a rewarding process for some, but others might find it time-consuming. Additionally, the availability of certain vintage tools can be limited, making them more expensive and harder to find. Conversely, modern tools, though readily available and often more user-friendly, can sometimes lack the charm and historical significance of their vintage counterparts.

For woodworkers considering an investment in either type, it is essential to weigh these factors carefully.

If you value historical craftsmanship and are willing to put in the effort to maintain your tools, vintage hand tools might be the right choice.

However, if you prioritize cutting-edge performance and ease of use, modern hand tools could better suit your needs. Ultimately, the decision depends on your individual preferences and the demands of your woodworking projects.

The Impact of Different Wood Species on Hand Tool Performance.

The performance and longevity of woodworking hand tools can be significantly influenced by the type of wood being worked on.

Understanding the characteristics of different wood species is crucial for optimizing tool efficiency and ensuring their durability.

Wood is generally classified into two categories: hardwoods and softwoods, each affecting hand tools in unique ways.

Hardwoods, such as oak, maple, and walnut, are known for their density and durability. These woods typically offer more resistance, which can cause faster wear and tear on hand tools.

When working with hardwoods, it is essential to keep tools sharp and well-maintained to prevent damage and ensure smooth operation.

Regular honing and periodic sharpening are necessary to sustain the edge of chisels, planes, and saws.

In contrast, softwoods, including pine, cedar and fir, are less dense and generally easier to work with.

While they pose less strain on hand tools, they can still cause issues such as resin buildup, which may lead to gumming up blades and reducing tool efficiency.

Cleaning and lubricating tools regularly can mitigate these effects, maintaining their performance over time.

When working with both hardwoods and softwoods, it is crucial to adjust tool settings appropriately.

For example, planing a hardwood might require a shallower cut to avoid excessive force and potential damage to the tool and wood.

Conversely, softwoods may allow for more aggressive cuts, but attention should be paid to avoid tear-out and splintering.

To ensure optimal performance and longevity of hand tools, a few maintenance tips are recommended.

Regular inspection of tools for signs of wear, such as nicks or dull edges, allows for timely maintenance.

Additionally, using appropriate lubricants for moving parts and keeping tools clean and dry can prevent rust and prolong their lifespan.

By understanding the impact of different wood species on hand tools and implementing proper maintenance practices, woodworkers can achieve better results and extend the life of their valuable tools.

Measuring and Marking Tools in Precise Hand Tool Work.

In the realm of woodworking, achieving precision is paramount, and this precision hinges significantly on the effective use of measuring and marking tools.

These tools are fundamental in ensuring that every cut, joint, and assembly aligns perfectly, thereby elevating the overall quality of the woodworking project.

Essential measuring and marking tools include rulers, squares, marking gauges, and dividers, each serving a specific purpose in the pursuit of accuracy.

Rulers are indispensable for measuring lengths and widths with exactness. Whether it’s a simple steel ruler or a more sophisticated measuring tape, these tools provide the baseline measurements needed for any project.

Squares, including the try square and the combination square, are crucial for verifying right angles and ensuring the squareness of edges and joints.

The precision offered by these tools prevents misalignments that could compromise the structural integrity of the final product.

Marking gauges are another vital tool in the woodworker’s arsenal. These tools allow for the precise marking of lines parallel to an edge, which is especially useful for tasks such as cutting joints or creating mortises.

The adjustable nature of marking gauges ensures that measurements are consistent and replicable across multiple pieces of wood.

Dividers, on the other hand, are used for transferring measurements and for scribing arcs and circles, adding another layer of precision to the woodworking process.

To use these tools effectively, it is important to maintain them in good condition. Sharp pencils or marking knives should be used for clear, accurate lines, while rulers and squares should be checked periodically to ensure they remain true.

Additionally, practicing proper measurement techniques, such as double-checking measurements and using a consistent point of reference, can significantly enhance the accuracy and consistency of your work.

The role of measuring and marking tools in woodworking cannot be overstated. These tools are the foundation upon which precision is built, enabling woodworkers to create pieces that are not only functional but also aesthetically pleasing.

By mastering the use of these essential tools, woodworkers can ensure that their projects meet the highest standards of craftsmanship.

Advantages of Traditional Joinery Techniques with Hand Tools.

Traditional joinery techniques, such as dovetail joints, mortise and tenon joints, and finger joints, offer numerous advantages when crafted with hand tools.

One of the primary benefits is the enhanced structural integrity that these joints provide. Unlike mechanical fasteners, traditional joinery techniques create interlocking wood connections that distribute stress more evenly, resulting in stronger and more durable assemblies.

This is particularly advantageous in furniture making and architectural woodworking, where longevity and robustness are paramount.

Aesthetic appeal is another significant advantage of traditional joinery. Hand-crafted joints exhibit a level of craftsmanship and attention to detail that machine-made joints often lack.

The visible dovetails on a drawer or the precise fit of a mortise and tenon joint add a touch of elegance and sophistication to the final piece.

These joints are not only functional but also serve as decorative elements that showcase the skill and dedication of the woodworker.

Additionally, the process of creating traditional joints by hand can be immensely satisfying. The tactile experience of working with hand tools, the sound of a chisel carving through wood, and the sight of a perfectly fitting joint coming together are deeply rewarding.

This hands-on approach fosters a deeper connection to the craft and a greater appreciation for the materials and techniques used.

Mastering traditional joinery techniques requires practice and patience. Beginners should start with basic joints and gradually progress to more complex ones.

It’s essential to understand the properties of different wood species and how they influence joint selection and execution. Consistent practice with hand tools will improve precision and efficiency over time.

These traditional techniques have versatile applications in various woodworking projects, from small boxes and drawers to large furniture pieces and structural elements.

Whether you are a hobbyist or a professional woodworker, the skills and knowledge gained from mastering traditional joinery will enhance the quality and appeal of your creations.

Evolution of Hand Tool Design and Industry Innovations.

The evolution of woodworking hand tool design has been marked by significant advancements and innovations throughout history.

From the rudimentary tools used by early civilizations to the sophisticated instruments utilized today, the transformation reflects an ongoing quest for efficiency, precision, and ergonomic excellence.

Historically, woodworking hand tools were crafted from readily available materials such as stone and bone.

With the advent of the Bronze Age, metals like bronze and iron became prevalent, revolutionizing the durability and functionality of these tools.

The Industrial Revolution further accelerated this evolution, introducing mass production techniques that made high-quality tools more accessible to the general populace.

This era also saw the development of specialized tools tailored to specific woodworking tasks, enhancing the craft’s precision and versatility.

In recent decades, significant advancements have been made in the materials used for hand tools.

High-carbon steel, stainless steel, and other alloy compositions have been employed to improve blade sharpness, durability, and corrosion resistance.

Additionally, the introduction of composite materials and advanced polymers has enhanced the ergonomics and comfort of tool handles, reducing user fatigue and increasing efficiency.

Modern technology has profoundly impacted hand tool design, bringing about innovations such as laser-guided measurements and digital angle finders.

These advancements have improved accuracy and ease of use, allowing woodworkers to achieve precise cuts and measurements with minimal effort.

Moreover, the integration of smart technology has led to the development of tools that can connect to mobile devices, providing real-time data and diagnostics to users.

The latest trends in the woodworking hand tool market include a growing emphasis on sustainability and eco-friendly materials.

Manufacturers are increasingly adopting practices that reduce environmental impact, such as using responsibly sourced wood for handles and promoting the longevity and repairability of tools.

Additionally, there is a rising interest in customizable tools that cater to the unique preferences and needs of individual woodworkers, further enhancing the user experience.

Overall, the evolution of hand tool design and industry innovations continues to shape the woodworking landscape, offering both amateur and professional woodworkers a diverse array of tools that combine traditional craftsmanship with cutting-edge technology.

Advanced Hand Tool Techniques to Elevate Craftsmanship.

In the realm of woodworking, mastering advanced hand tool techniques can significantly enhance the quality and precision of your projects.

Delving into intricate carving, inlay work, and fine joinery can transform your craftsmanship, allowing you to create pieces that are not only functional but also artistically impressive.

Intricate carving is a technique that demands patience and precision. It involves detailed designs carved into the wood’s surface, often using chisels, gouges, and knives.

Mastering this technique requires a steady hand and a keen eye for detail. Begin with simple patterns and gradually progress to more complex designs.

Tools should be kept sharp, and wood selection is crucial; softer woods like basswood or butternut are ideal for beginners.

Projects such as decorative panels or custom furniture accents are excellent ways to showcase your carving skills.

Inlay work, another sophisticated technique, involves embedding materials such as wood, metal, or shell into the surface of a woodworking project.

This technique adds visual interest and can be used to create intricate patterns or images. To achieve precise inlay work, start by carefully outlining the design on the wood surface. Next, use a sharp chisel to carve out the recess, ensuring it matches the dimensions of the inlay material.

Patience and precision are paramount, as any mistake can detract from the overall aesthetic.

Inlay work is often used in creating custom tabletops, musical instruments, and decorative boxes.

Fine joinery is the hallmark of superior woodworking. Techniques such as dovetail joints, mortise and tenon joints, and box joints not only provide structural integrity but also add an element of craftsmanship.

Dovetail joints, known for their strength and aesthetic appeal, are commonly used in drawer construction.

Mortise and tenon joints, ideal for frames and tables, offer durability and a seamless appearance. Box joints, with their interlocking fingers, are perfect for creating sturdy boxes and chests.

Mastery of these joints involves precise measuring, cutting, and fitting, often achieved with saws, chisels, and marking gauges.

By incorporating these advanced hand tool techniques into your woodworking repertoire, you can elevate your craftsmanship and create projects that are both structurally sound and artistically refined.

Whether you are working on intricate carvings, detailed inlays, or fine joinery, the key is to practice consistently and remain dedicated to honing your skills. The results will speak volumes about your dedication and expertise in the art of woodworking.

Tool Selection for Specific Projects or Styles of Woodworking.

Choosing the right tools for your woodworking projects is fundamental to achieving the desired outcome. The selection process should begin with a clear understanding of the project’s requirements, the type of wood being used, and your personal preferences and skills.

Different woodworking styles, such as furniture making, cabinetry, and fine woodworking, each necessitate a unique set of tools tailored to their specific demands.

For furniture making, a solid foundation of basic hand tools is essential. These typically include a combination square for precise measurements, a set of chisels for detailed work, and a reliable hand saw for cutting various wood types.

Additionally, a smoothing plane is invaluable for achieving a smooth finish on visible surfaces.

When working on furniture, the choice of hardwoods like oak or maple often requires robust and sharp tools to handle the density and grain patterns effectively.

Cabinetry, on the other hand, involves more intricate joinery and often requires specialized tools.

A dovetail saw is indispensable for creating tight, interlocking joints, while a router plane can help achieve even grooves and dados.

Alongside these, a shoulder plane is useful for refining tenons and other fine adjustments.

For cabinetry projects, it’s common to work with both hardwoods and softwoods, necessitating a versatile toolkit that can handle different wood characteristics.

Fine woodworking, which focuses on intricate details and high precision, demands a more refined set of tools. A set of fine chisels, along with a block plane, are crucial for achieving delicate, precise cuts.

Additionally, a marking gauge ensures accuracy in layout lines, while a card scraper helps in obtaining a glass-like finish on the wood surface.

Fine woodworking often employs woods like cherry or walnut, which require tools capable of delicate handling to maintain the wood’s natural beauty.

Ultimately, the key to successful tool selection lies in matching the tools to the specific requirements of the project and the wood type while considering your comfort and proficiency with each tool.

This approach not only enhances the efficiency and quality of your work but also ensures a more enjoyable woodworking experience.

Tips for Setting Up an Efficient Hand Tool Workspace.

Creating an efficient hand tool workspace is essential for maximizing productivity and ensuring a comfortable working environment.

A well-designed workspace can significantly impact the quality of your woodworking projects.

Tips For Setting Up An Efficient Hand Tool Workspace:

1. Workbench Design: A sturdy and well-constructed workbench is the cornerstone of any hand tool workspace.

a. Ensure your workbench is at a comfortable height to minimize strain on your back and shoulders.

b. A height of around 34 to 36 inches is generally suitable for most woodworkers.

c. Additionally, consider incorporating vises and bench dogs to secure your workpieces effectively.

2. Tool Storage: Organized tool storage is crucial for maintaining efficiency.

a. Wall-mounted pegboards, tool racks, and cabinets can help keep your tools within easy reach while keeping the workspace clutter-free.

b. Labeling tool storage areas can also save time and reduce frustration when searching for specific tools.

c. Custom-built tool chests and drawers can provide additional storage and help protect your tools from dust and damage.

3. Lighting: Proper lighting is essential for any woodworking workspace.

a. Adequate illumination helps reduce eye strain and ensures precision in your work.

b. Natural light is ideal, so if possible, position your workspace near windows.

c. Supplement natural light with adjustable task lighting to focus on specific areas of your workbench.

d. LED lights are a great option due to their brightness and energy efficiency.

4. Ergonomics: Ergonomics play a vital role in creating a comfortable and efficient hand tool workspace.

a. Ensure that your workbench, stool, and tool storage are arranged to minimize unnecessary movements and awkward postures.

b. Adjustable workbenches and ergonomic stools can help maintain proper posture and reduce fatigue during long working sessions.

5. Organization and Workflow: Organizing your tools and materials in a logical manner can greatly enhance productivity.

a. Group similar tools together and store frequently used items within arm’s reach. Consider setting up dedicated zones for different tasks, such as cutting, sanding, and assembly.

b. This organization not only streamlines your workflow but also helps maintain a tidy and safe workspace.

By paying attention to these aspects, you can create a hand tool workspace that is not only efficient but also enjoyable to work in.

A well-thought-out workspace can make a significant difference in the quality and ease of your woodworking projects.